3D Printing for Lightweight Ergonomic Chaise Longue.

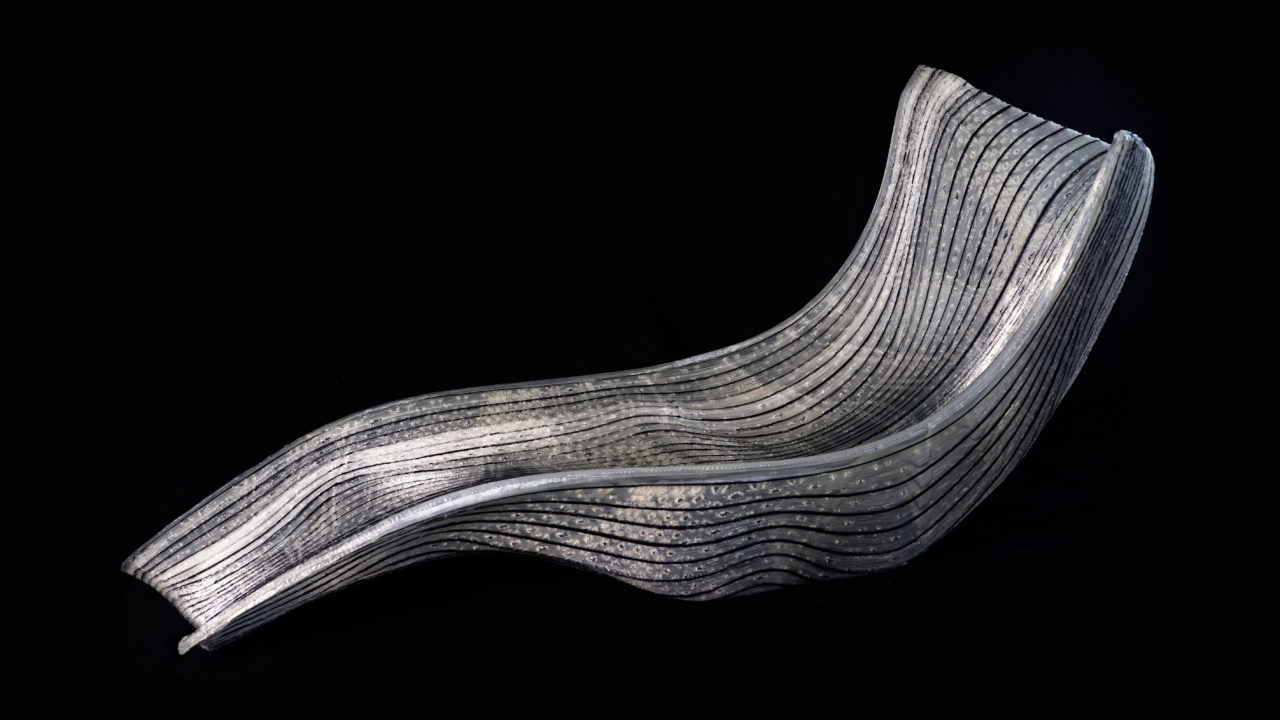

With its ergonomic design, intricate details and its optimized geometry, the robotically 3D-printed LevisErgon chair showcases the potential of a strong interplay between digital fabrication and computational design. Consequently, the chair could be 3D-printed with a thickness of only 2mm, enabling the weight of the deckchair, with its dimensions of 1.7m x 0.7m x 0.7m, to achieve less than 15kg.

On the one hand, lightness has significant benefits in architecture: efficient transport, easy assembly and reduced embodied energy. On the other hand, 3D Printing (3DP) technology opens up the potential of mass-customization, allowing highly detailed complex design. Notwithstanding its great potential, plastic extrusion based 3D-printed objects tend to be heavier than parts fabricated using conventional machining or injection moulding. This is due to a fundamental limitation: the layer adhesion along the z-axis is weak. To address this limitation, one usual option is to print with a large material thickness in order to increase the inter-layer contact area.

In contrast, the design of the chaise longue LevisErgon is structurally optimized by adapting to the structural-flow that results from the physical interaction of human and object. The individual plastic layers are printed in variable layer-height and printing-speed, allowing each layer to follow computationally generated force fields. With this approach, increasing the weight can be avoided and the material can be saved while maintaining structural integrity.

The computationally generated geometry showcases several design features which apart from the unique aesthetics, also have a structural role:

- the inner, three-dimensional wave structure stiffens the millimeter-thin plastic shell

- the honeycomb-shaped holes reduce material, where it is not needed

- the variation in layer-height avoids delamination along the layer-seams

The first prototype is printed out of Polylactic Acid (PLA) in different colors, a recyclable and biodegradable material derived from natural sources, such as starch. The next step is to further improve stability and to reinforce locally the plastic object with 3D-printed continuous Carbon Fiber-Reinforced Polymer (CFRP). Therefore, a custom robotic extruder is developed, which allows to 3D print with multiple lightweight materials such as PLA and CFRP in an uninterrupted, single process.

The LevisErgon is developed by MAS ETH DFAB students Moon Young Jeong and Frank Cheng-Huang Lin, and supervised by (Digital Building Technologies, ETH Zurich) especially for their individual thesis and the ETH Zurich at the Olma Fair 2018.

The project is under development, further detail information will be updated soon.