The HiRes Concrete Slab is an ultra-efficient structural element that showcases the unique advantages of 3D-printed formwork: material reduction, integrated building services, and the spectacular aesthetic of free form. The slab implements these principles in a real-world building, demonstrating a disruptive new construction method. This new approach can have a significant positive impact on the built environment: reducing embodied carbon and operational energy, increasing user comfort, and giving architects unprecedented design freedom.

NEST HiLo Unit

The soffit of the HiRes Concrete Slab was designed by DBT for one of the two closed office spaces in the HiLo Unit. Located in Dübendorf, Switzerland, the HiLo is a two-storey collaborative and flexible workspace within the Next Evolution Sustainable Building Technologies (NEST) platform. The main architectural feature of the unit is the HiLo vaulted concrete roof, a structure developed by BRG. The shell houses a double-height shared open space and two boxes for private office spaces. One of these offices is covered by the HiRes Slab and uses the Adaptive Solar Facade developed by A/S.

NEST is a living lab, aiming to test home and working environments for the future in real-life situations. The office space below the HiRes Slab will be used by an EMPA Robotics team of researchers, focusing on the use of drones for building maintenance.

Material Reduction

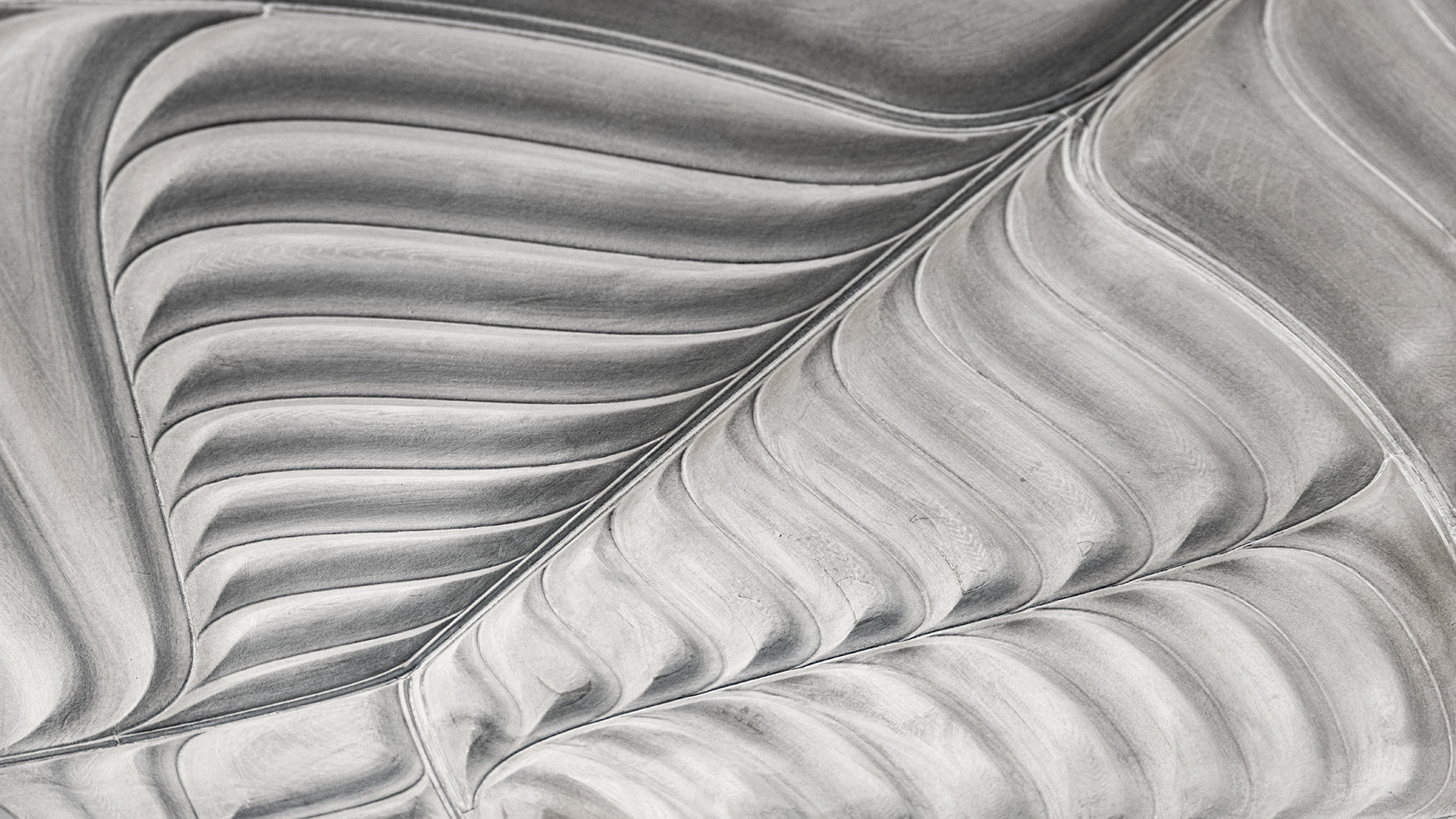

Based on the structural concept developed by BRG, the HiRes Slab is a thin, doubly curved funicular shell. Vertical stiffeners transfer loads to the boundary supports through compression forces only. The forces are concentrated in the corners, where their horizontal thrust is distributed to post-tensioned ties. Thus, material is placed only where it is structurally needed, according to the flow of forces through the shell. This approach results in a 70% reduction of material compared to a standard reinforced concrete slab.

HIgh-rESolution CONCRETE

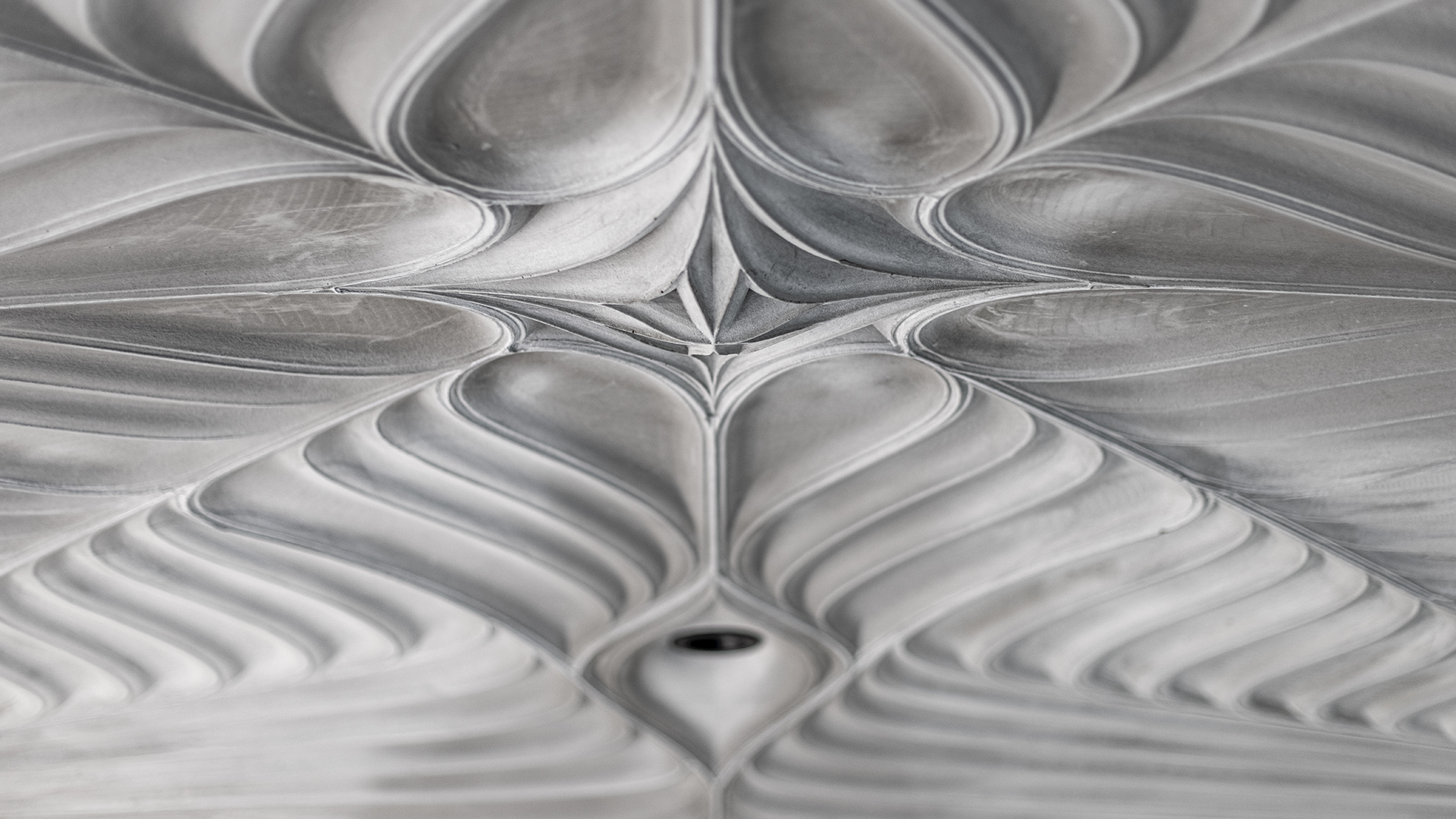

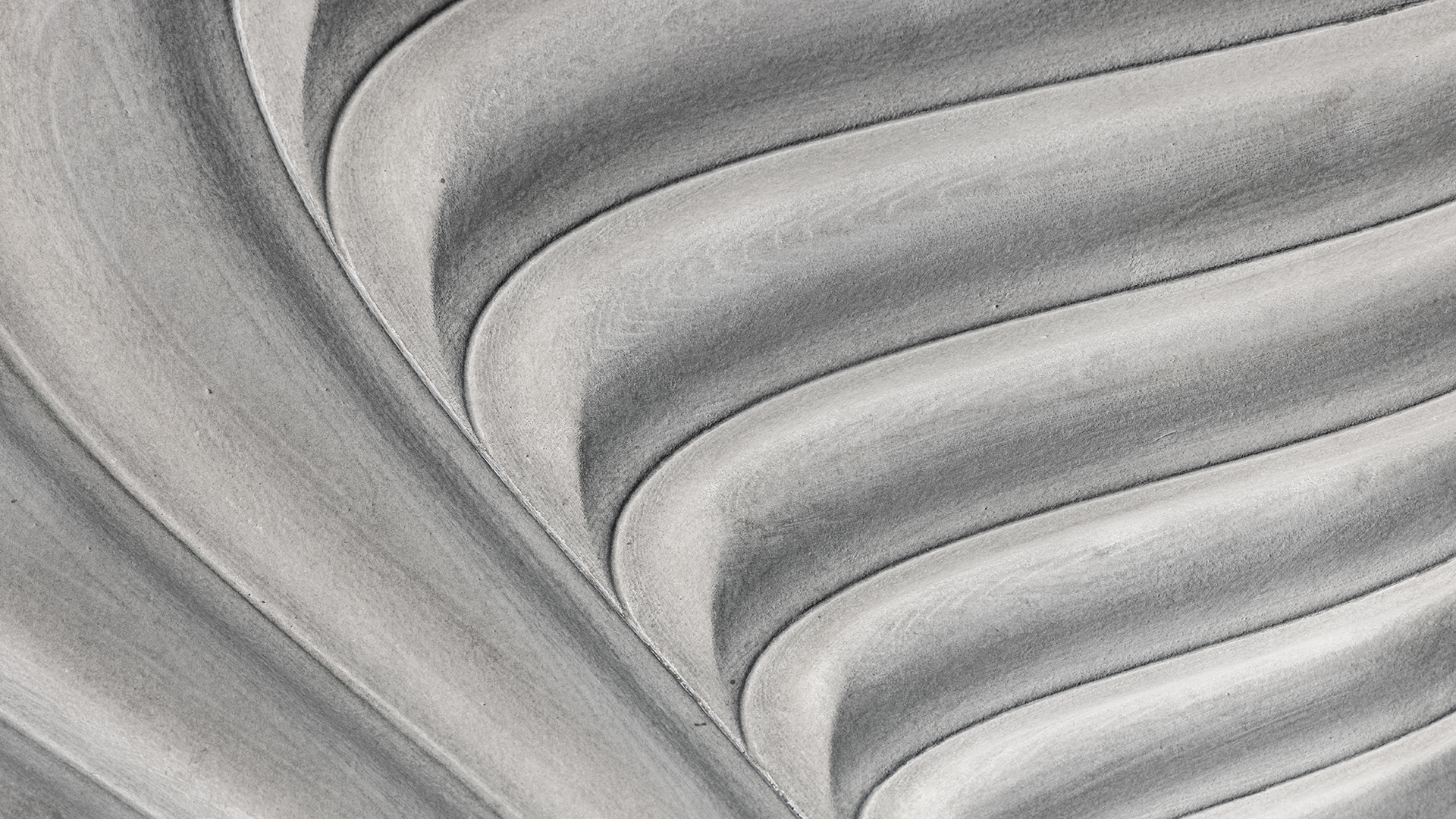

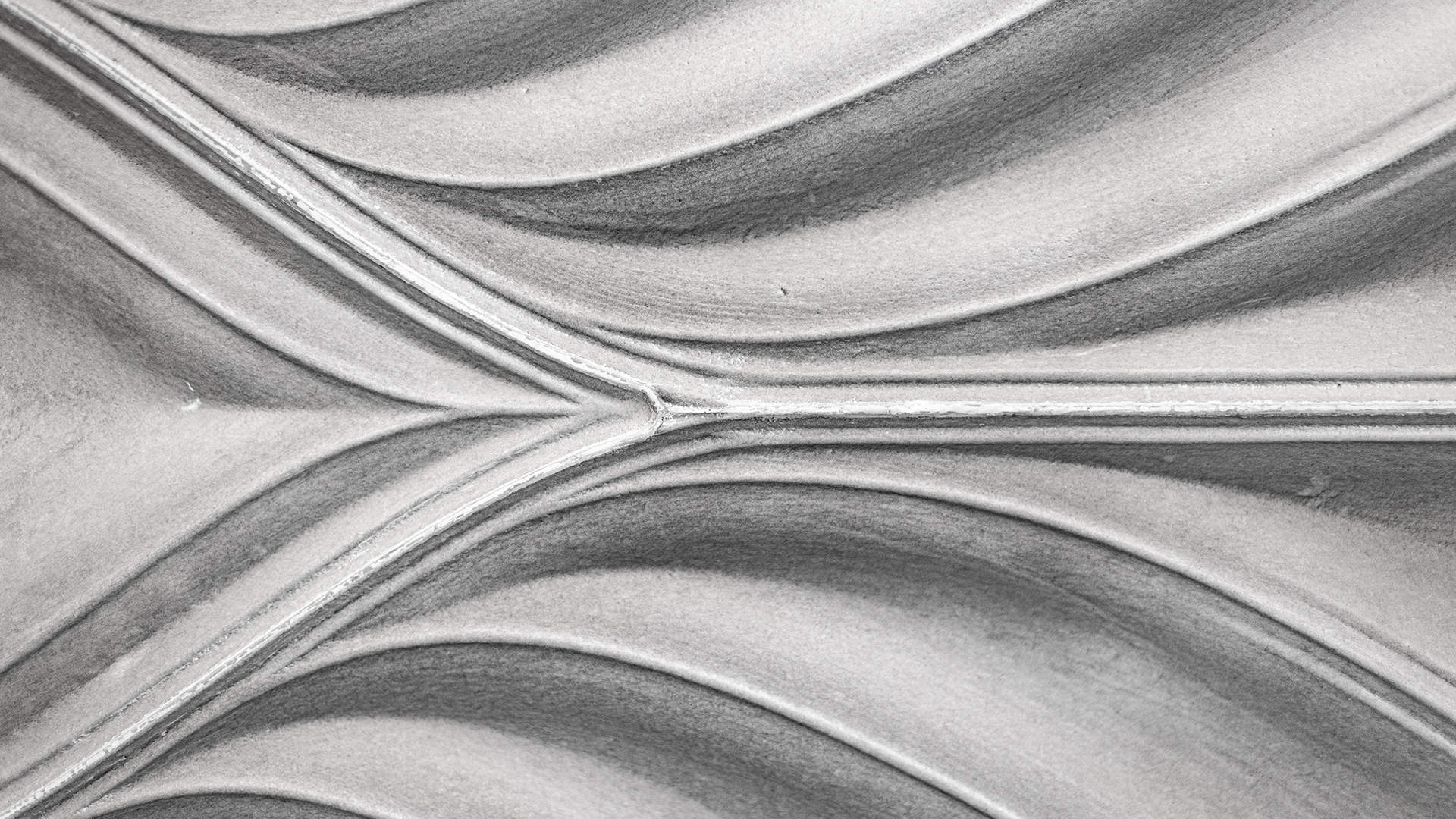

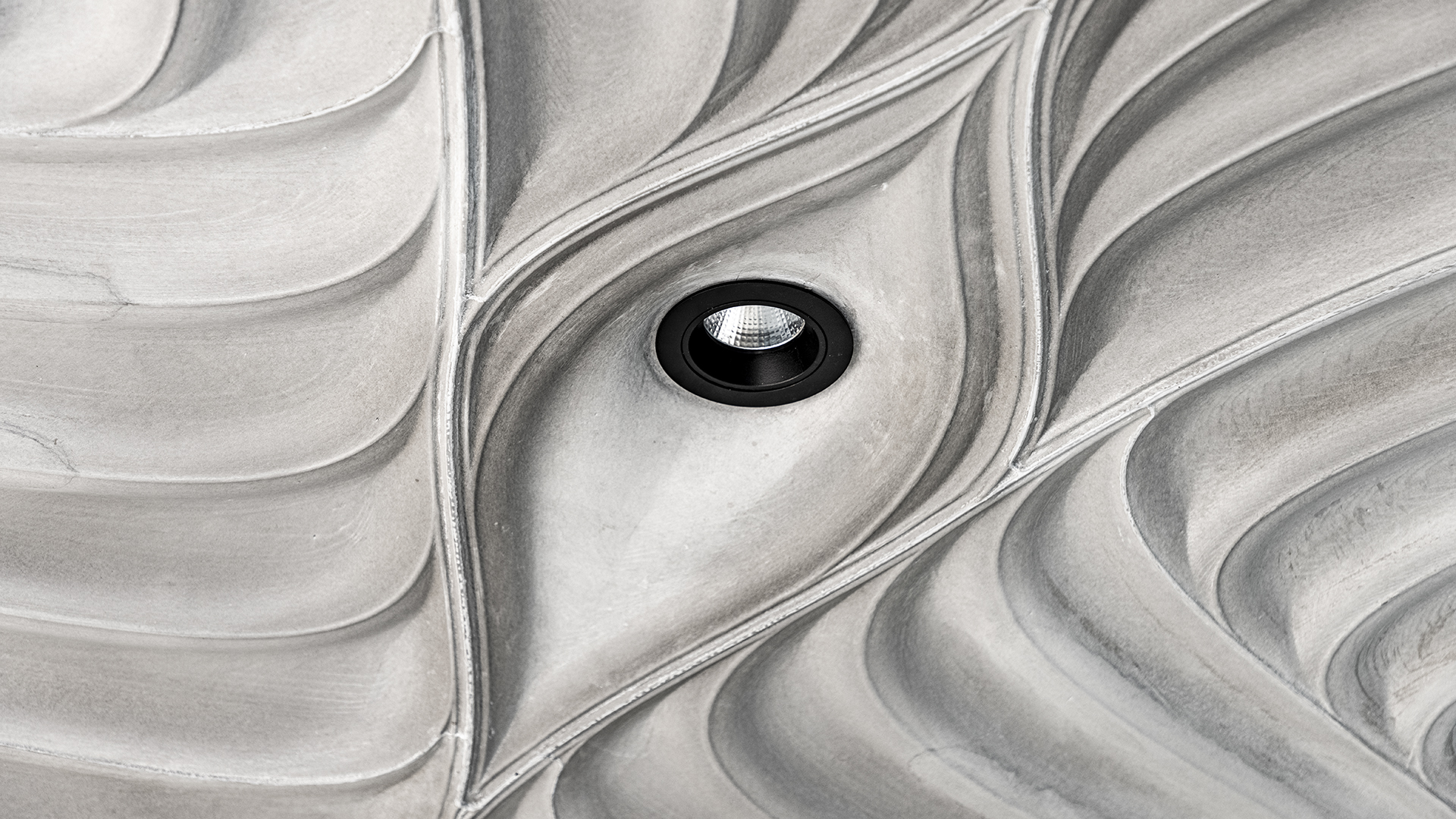

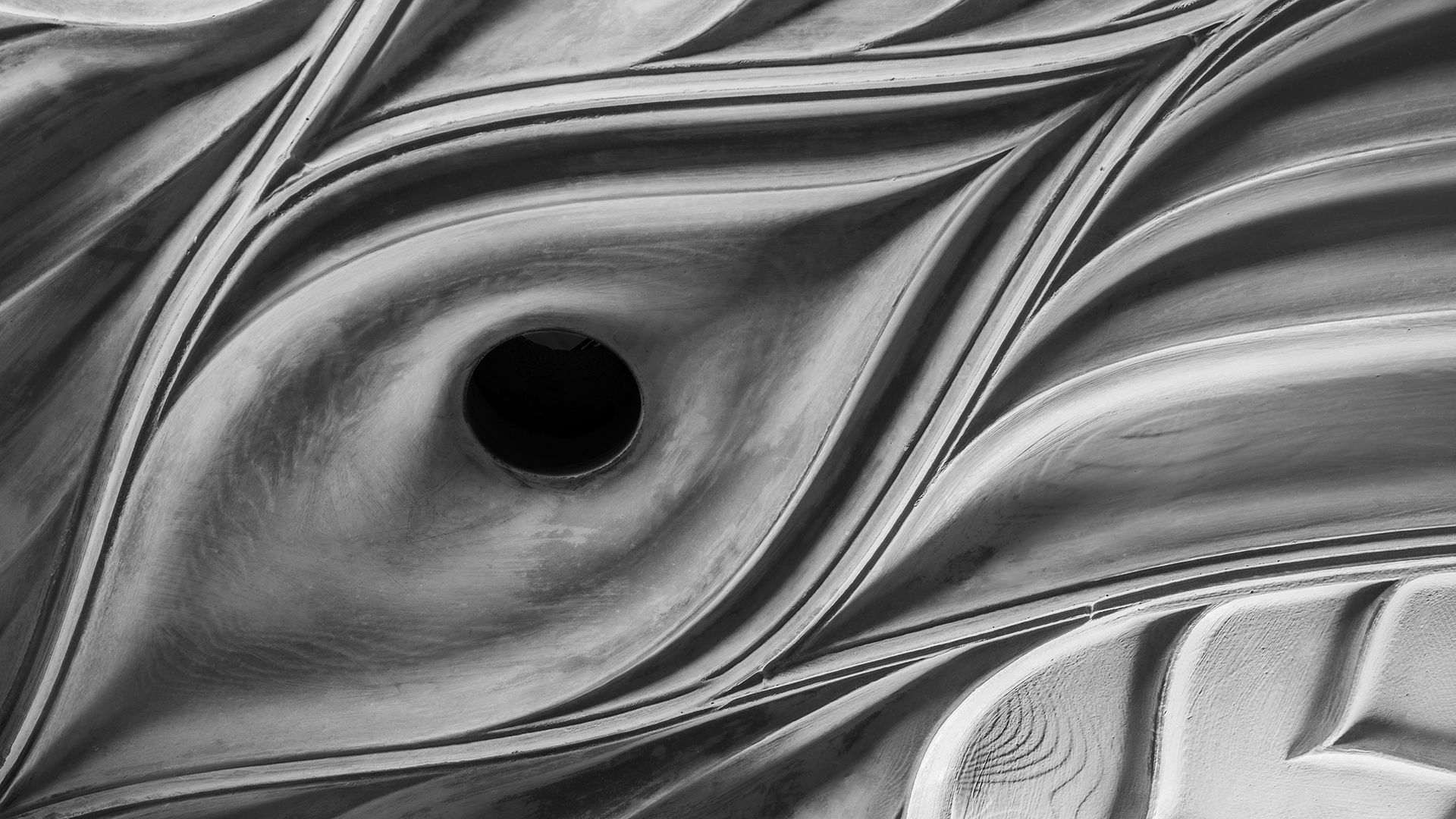

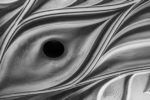

The highly articulated soffit of the HiRes Slab enhances the acoustic and spatial quality of the office through a unique aesthetic of flowing contours that reach their highest density in a central peak and fade out towards the perimeter. Primarily, the pattern generation is based on several competing constraints that reflect the fabrication process and the functional requirements of the slab. Furthermore, the pattern aims to achieve a balanced composition within the asymmetrical vault while reacting to the optimal position of the lights and ventilation outlets within the shallow vault.

The profiles of the contours follow a specific hierarchy and respect strict fabrication constraints that ensure demouldability and a high quality architectural concrete surface. The most prominent contours are a result of seams between adjacent 3D-printed formwork parts. Secondary contours have a shallower profile, subordinate to the primary seams, and adapt to the functional elements of the slab, disappearing around the lights and becoming narrower in front of the ventilation outlets.

Integration of Building Services

Previous research in digital concrete has focused almost exclusively on reducing the embodied energy of buildings through material reduction. However, the embodied energy only represents a small percentage of the total life-cycle energy of buildings, most of which comes from the operational phase. In this regard, the HiRes Slab pioneers a new approach in digital fabrication for concrete, achieving significant energy savings by using the topological voids in the structural bounding box to integrate optimised building services.

The HiRes Slab integrates a heating and cooling network developed in collaboration with A/S, that informs the secondary contours of the soffit, essentially acting as a highly efficient radiant panel. Additionally, the active ventilation system, first developed for the WEF Funicular Floor, further enhances the thermal performance. The geometry of the air ducts is optimised using high-resolution numerical modelling and produced using polymer extrusion 3D printing for Submillimeter Formwork. Combining digital design and fabrication results in an energy-efficient slab that improves thermal comfort for occupants by reducing reaction times, while simultaneously retaining the benefits of thermal inertia.

3D PRINTED FORMWORK for In-situ Concrete

Digital modelling tools offer today unlimited design freedom in a virtual environment. Architects use generative processes to design unexpected shapes of indefinite complexity that cannot otherwise be imagined beforehand. Nevertheless, conventional construction methods for concrete, using timber and glass fibre moulds, are unable to physically reproduce objects of such complexity.

To tackle this limitation, the innovative formwork system developed by DBT uses a combination of digital fabrication processes to efficiently fabricate high-quality concrete surfaces. The system was initially developed for precast concrete elements for the Smart Slab, and was adapted for the in-situ construction of the HiRes Slab.

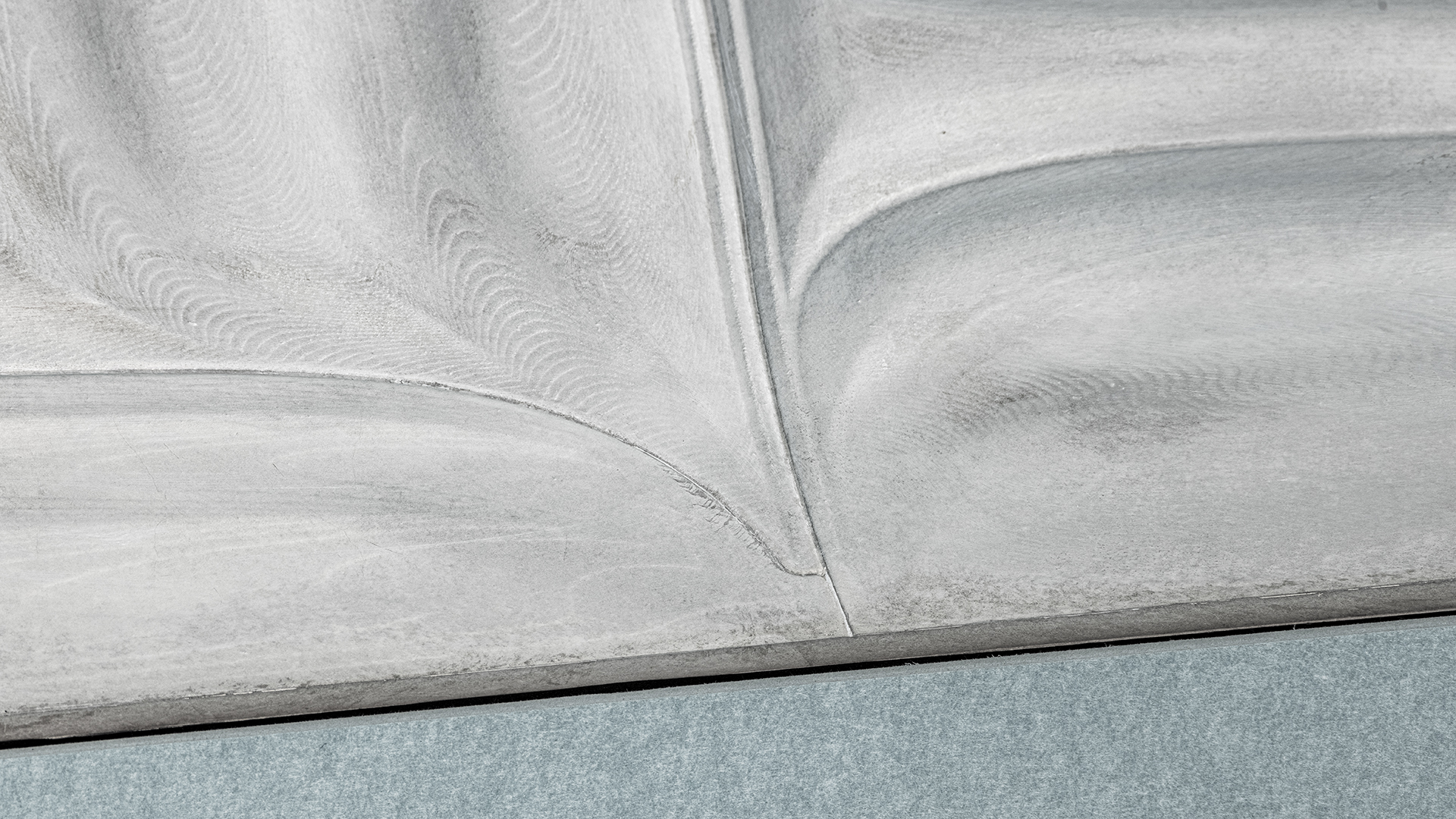

There are three main components within the formwork system. Firstly, 43 binder-jet 3D-printed formwork parts define the bulk of the surface. The 3D-printed parts are only five centimetres in thickness to reduce material and production costs. Secondly, a laser-cut waffle supports the thin 3D-printed parts to ensure a precise transition between the flat surface of the standard scaffolding system and the uneven lower surface of the 3D-printed parts. Combining the two processes ensures a fast, resource-efficient process, designed to be flexible enough to deal with on-site tolerances.

The third fabrication process is polymer extrusion 3D printing, which complements binder-jetting to devise the integrated functional features of the slab developed in collaboration with A/S: integrated heating and cooling, ventilation ducts, and provisions for lighting features.

Multidisciplinary Research

The structural concept of the HiRes Slab was developed by the Block Research Group (BRG) at ETH Zürich. The integrated multifunctional building systems and the digital fabrication process were developed by an interdisciplinary team from Architecture and Buildings Systems (A/S) and Digital Building Technologies at ETH Zürich.