Prōtóplasto is an ultralight media installation exhibited at the innovation hub “Futurama” in Aargau, Switzerland. It is created with a novel constructive system pairing two new technologies: an innovative 3D printing method for polymers with very high build up rates which are similar to concrete extrusion, and 3D printed connections whose bespoke geometry enables support-free self-interlocking assembly of modular components. The word Prōtóplasto stems from the Greek word “πρωτόπλαστος” (prōtóplastos) meaning “the first formed”.

Prōtóplasto aims to introduce a new perspective on the use of plastics in architecture. The exemplary structure leverages multiple digital fabrication technologies in order to achieve moldless and waste-free construction. Protoplasto is designed entirely with custom computational tools that establish design and fabrication relations of its subparts, allowing the designer to adapt its form to different settings and locations.

Why plastic?

Plastics in architecture have unique properties in terms of weight-to-strength ratio, customizable material properties, low material costs, and hold potential for recyclability thus extending their life cycles. The lightweight quality of the material evident in products like fiberglass has embodied historically the utopian image of cheap, transportable, bespoke, and organic buildings that could be accessible to all. While the fascination of the material soon transcended to light membranes and tensile structures used still today, the production of entire building components out of plastics was put to rest until recent years. The advent of 3D printing and especially Material Extrusion provided a cost-effective method, accessible to all, for creating customizable plastic parts of large dimension using thermoplastic feedstock without molds or falsework.

Prōtóplasto is a temporary media installation that explores the themes of transparency and lightweight construction, introducing innovative approaches to both on-site and off-site fabrication. Embedded in every aspect of the pavilion—from its initial concept to its geometric articulation and manufacturing methods—design computation plays a crucial role. This integration promotes a multi-scalar exploration of geometry and materials, with a high degree of prefabrication. The resulting system enables a custom, modular construction process that does not require any scaffolding during assembly. Moreover, the pavilion is designed for disassembly, ensuring that all materials can be separated and recycled, or repurposed.

Hollow-Core 3D printed columns

The pavilion features a modular arrangement of mushroom columns covering an area of 65 square meters with a specific weight of only 3.8kg/m2. Its columns are fabricated using an innovative 3D printing method known as Hollow-Core 3D Printing (HC3DP), which extrudes large tubular beads rather than solid ones. This novel approach has multiple advantages as it not only significantly increases the possible built-up rates,it does so by reducing material consumption and increasing the transparency of the print. The tubular geometry of the beads is made possible with the use of a custom nozzle and the introduction of positive air pressure. The nozzle splits and forms the molten plastic into a thin-walled bead around an empty core. Compressed air inflates the hollow bead and prevents it from collapsing while the material cools below the glass transition temperature. Thus, HC3DP pushes polymer 3D printing to an architectural-relevant scale, as a printed layer ranges from 10-24 mm while the build-up rate is comparable to concrete 3D printing. This technique allows for the production of 2.2-meter-tall columns in approximately 5 hours, using only 20 kg of material. When compared to traditional pellet extrusion systems that produce solid beads, HC3DP offers up to an 80% reduction in material use, showcasing significant efficiency and sustainability.

The foundation of these columns includes custom concrete footings that are cast using HC3DP formwork. This approach not only ensures stability but also extends the distinctive texture of the HC3DP columns to the base, creating a cohesive visual effect throughout the pavilion’s structure.

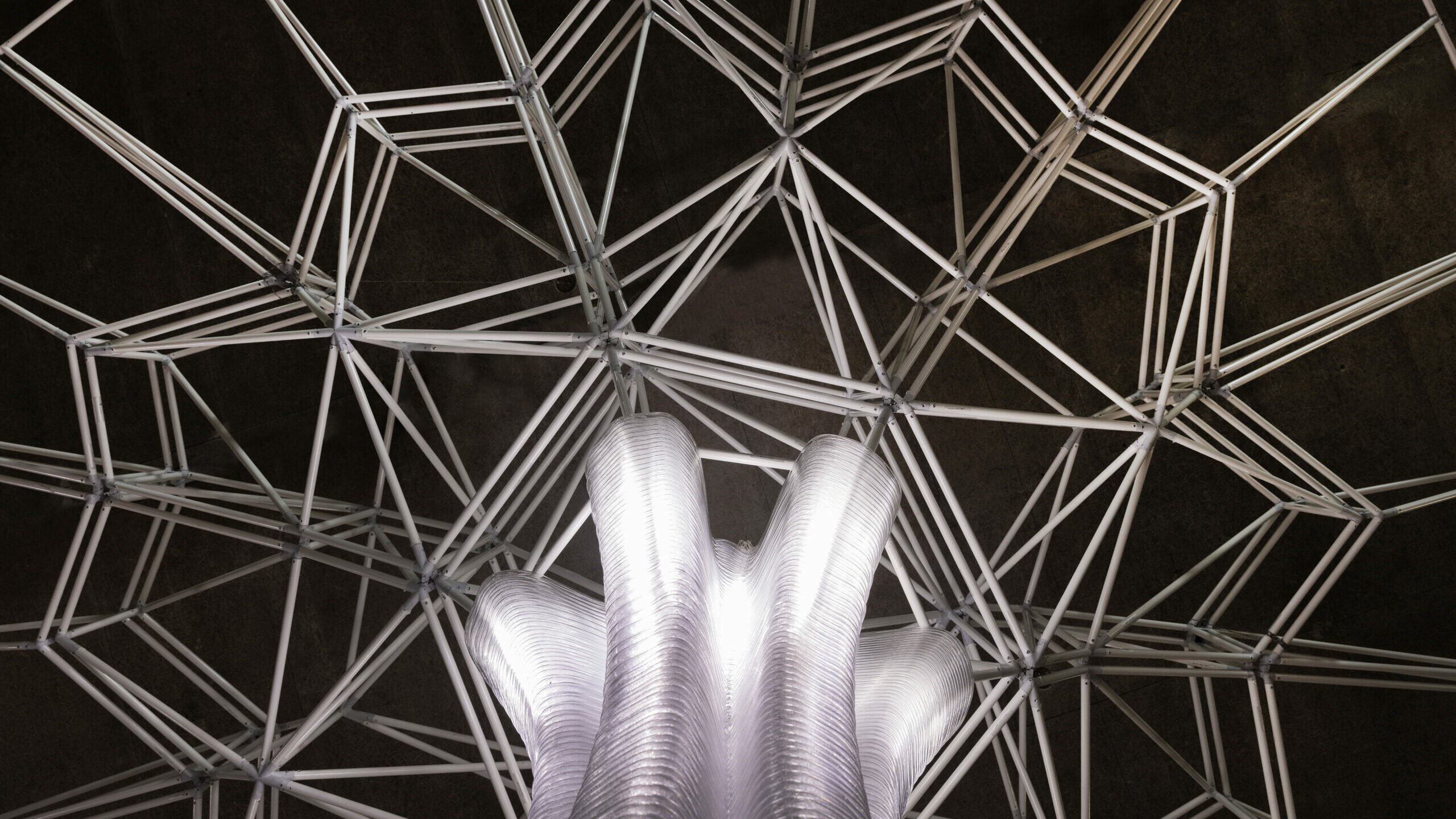

MOdular self-interlocking 3D printed roof

The structure’s innovative design and non-traditional layout necessitate a custom space frame. This spatial frame is carefully designed to be light enough to be supported by the ultralight HC3DP columns, yet sufficiently rigid to span the considerable distances between them and accommodate the horizontal outer overhang. The space frame’s complex topology is further adapted for a modular, support-free radial assembly, with each element specifically tailored to match its corresponding column and position within the overall structure.

The intuitive self-interlocking assembly of its bespoke modules is made possible with highly articulated self-guiding joints which interlock with gravitational force. These joints, designed to lock into place upon correct positioning, are designed with a custom computational framework that takes into account both fabrication limitations and the semi-constrained assembly sequencing. Produced using HP’s MultiJet Fusion technology, the joints are lightweight, high-performance, and feature high resolution, enabling a reversible roof structure through dry, self-interlocking connections.

The roof modules are specifically designed for ease of handling, enabling single-person on-site assembly, with an average weight of 3.7 kg per module. The assembly process involves as little as one person, adding modules in a radial pattern until the full ring is complete. Thanks to the segmentation approach, all column-roof pairs can be assembled simultaneously, allowing to crowdsource the assembly without requiring specialized skills. Additionally, the modules’ light weight and self-interlocking mechanisms present opportunities for assembly by autonomous or remotely operated drones in the future.

Industry Partners

This exhibition is made possible with support from industry. We would like to thank especially Halter AG for sponsoring the space and the vernissage, Castioni Kunstoffe for sponsoring the polymer tubes for the roof and SAEKI Robotics for allocating robot time in their 3D printing facilities.

We would like to acknowledge the effort and contributions of the class ‘23 students of the MAS in Architecture and Digital Fabrication at ETH Zurich.