Building complex concrete elements that are optimized for resource efficiency requires custom formwork, which is often wasteful and labor-intensive to produce. FoamWork explores how foam 3D printing (F3DP) can be used to create unique shapes for functional stay-in-place or temporary and recyclable formwork in concrete casting. The printable mineral foams based on recycled waste are developed at ETH Zürich in collaboration with FenX AG.

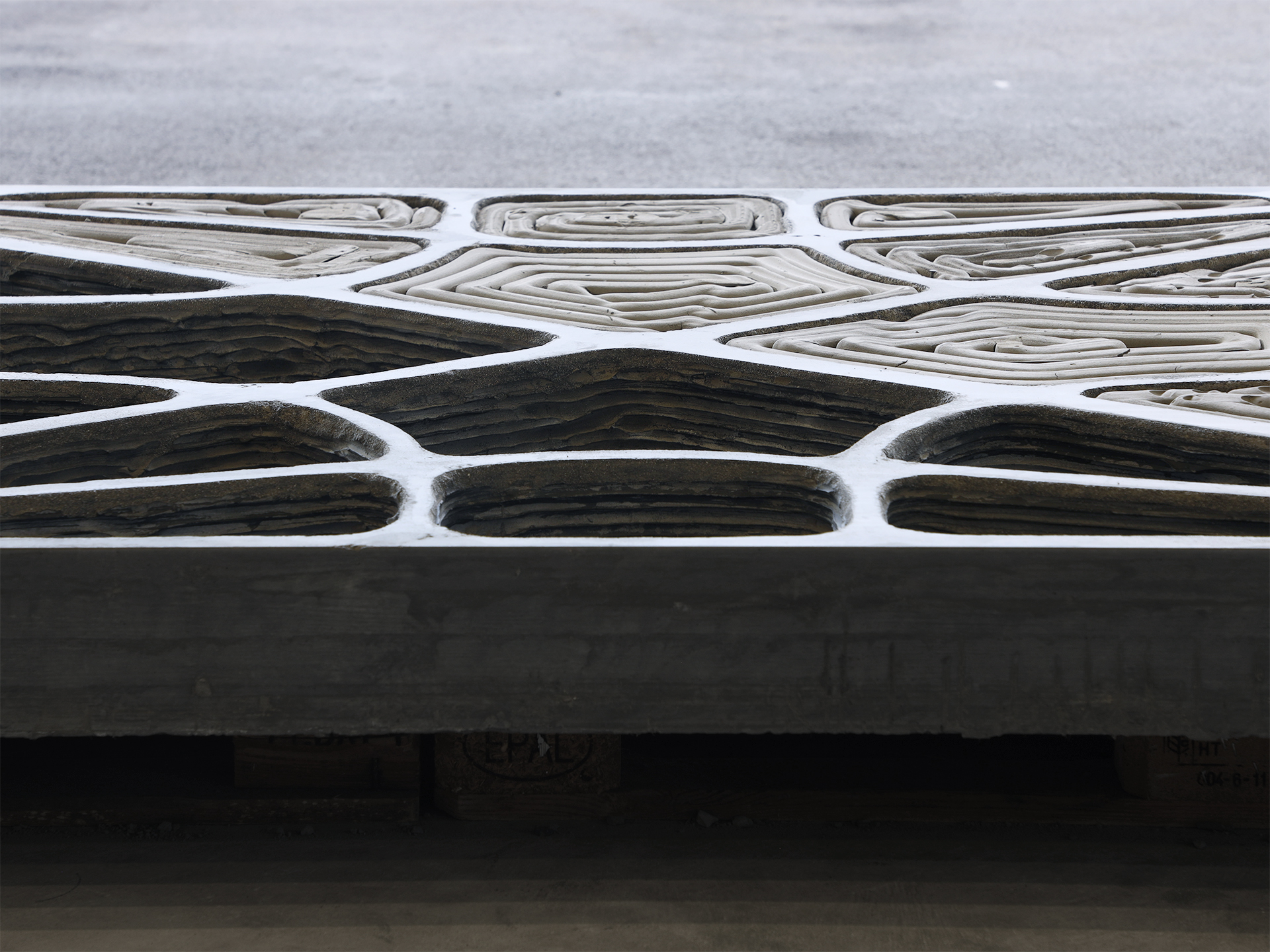

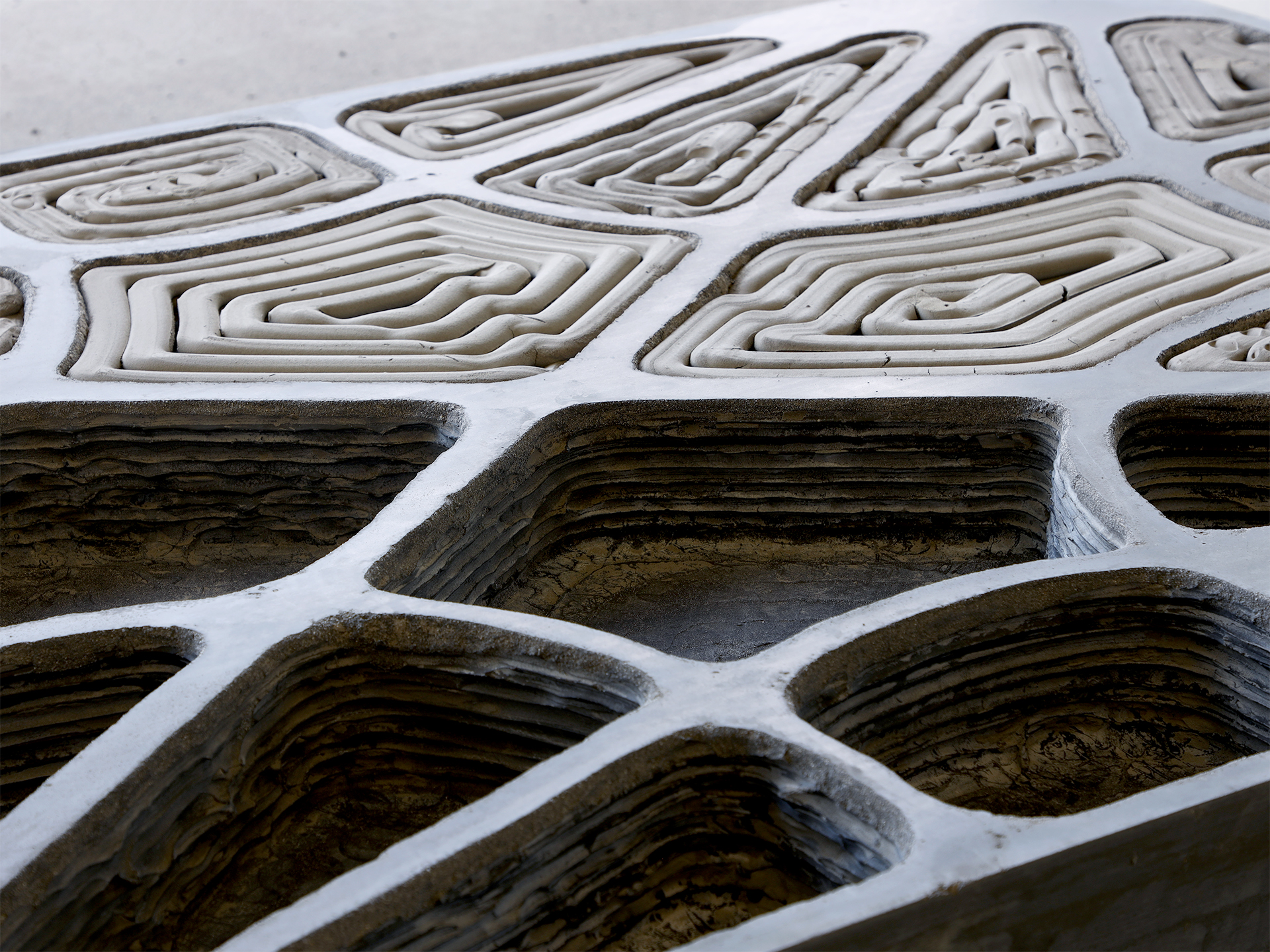

A prototype demonstrates this approach with the generic geometry of a 2 x 1.3m ribbed slab with point supports in every corner. The rib layout follows the isostatic lines derived from the principal stress pattern. The resulting geometry requires 24 formwork elements in 12 unique shapes.

All foam elements are fabricated with a robotic foam 3D printing (F3DP) setup. They are placed manually inside a conventional timber perimeter formwork before casting ultra-high-performance fiber-reinforced concrete (UHPFRC). After curing, the timber formwork is removed from the prototype and the structural building element is completed.

This novel fabrication approach is envisioned to significantly impact the responsible and sustainable consumption of resources and energy in the building industry. It enables the manufacturing of geometrically complex foam elements that were previously unfeasible and wasteful to produce with conventional methods. The foam shapes produced with F3DP can be used as stay-in-place applications or removed and recycled for printing the next formwork.