The Digital Bamboo pavilion explores the innovative combination of a bio material with digital fabrication. Bamboo is an excellent sustainable building material, because of its rapid growth and very low weight-to-strength ratio. Customized computational tools were developed to design the ultra-lightweight structure, whose bespoke connections were manufactured using 3D printing technology. The structure covers more than 40 sqm with a total weight of only 200 kgs. The Digital Bamboo pavilion showcases a filigree and engaging architecture that surpasses the standardized space frame vocabulary.

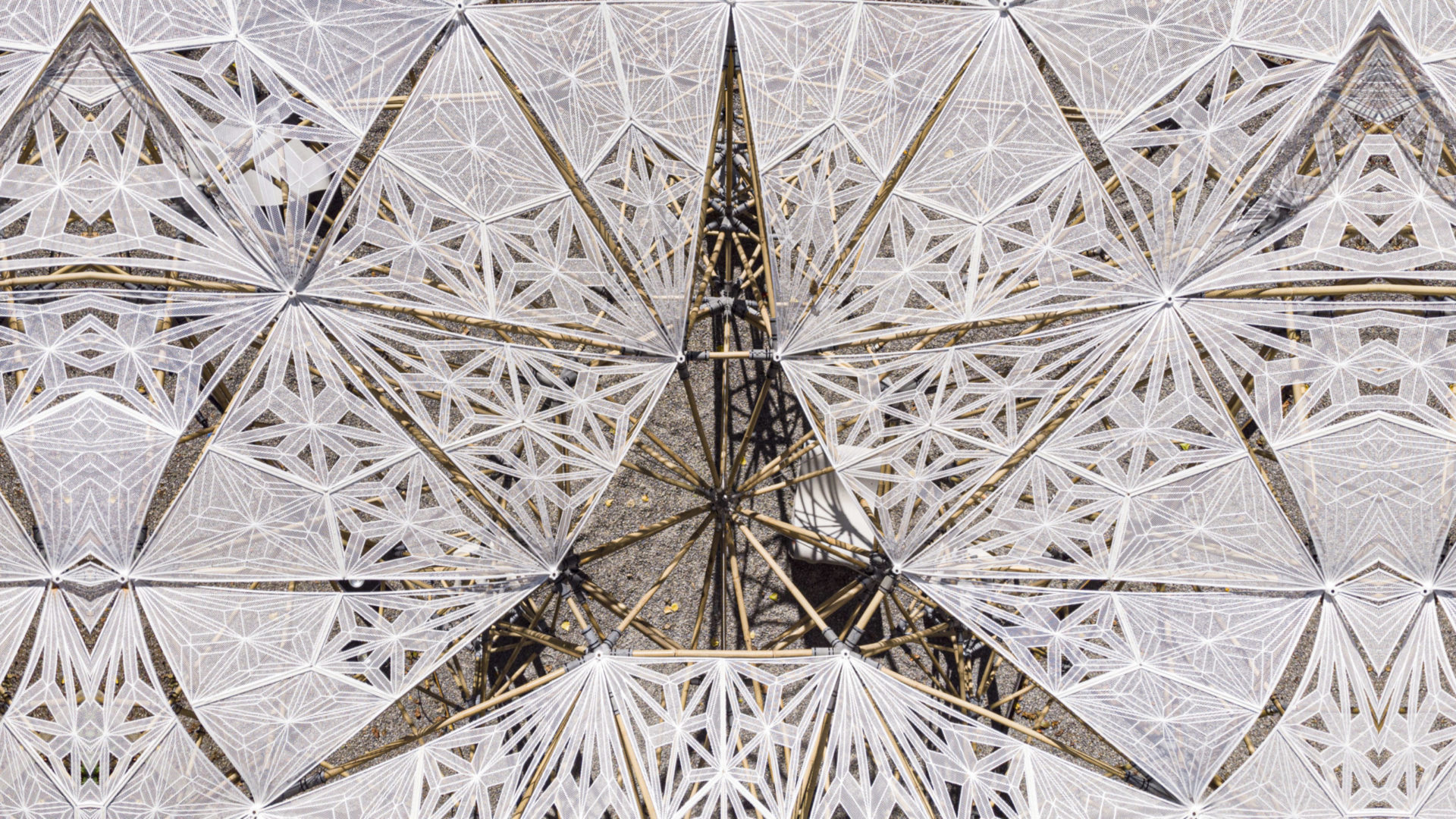

Computational design allows the optimization and formal exploration of complex structures. The high-performance structure covers a large area, cantilevering almost 5 meters in three directions whilst requiring minimal support. The main load-bearing system is defined by a spatial truss reinforced by post-tensioned cables. The geometry of the pavilion, consisting of more than 900 bamboo elements, was form-found using specifically developed digital tools.

The bamboo elements are connected via a new system based on 3D printing technology. The generation of the connections was automated thanks to a digital process and developed to fulfil mechanical requirements.

Their intricate geometry encapsulates necessary functions such as tolerances for assembly and bamboo inhomogeneities, connections to the shading panels, labelling, and cable fittings. In parallel, their volume is minimized to save time and cost. A hybrid strategy using MultiJet Fusion technology and Direct Metal Laser Sintering was used to manufacture the 380 bespoke connections.

The shading panels of the pavilion are designed through a custom computational process and fabricated through add-on 3D printing of a recyclable UV resistant thermoplastic on a lightweight lycra textile. 3D printing stiffens and shapes the fabric into flexible bespoke panels. The composite elements are locally reinforced reducing the amount of material used.

The construction system developed for the Digital Bamboo pavilion aims to reduce the logistic efforts of construction while exploiting the advantages of digital fabrication for a more sustainable building culture. Following the principle of distributed prefabrication, the complexity of the structure is encapsulated in small parts that can be fabricated all over the world using 3D printing. These custom parts can be used to construct high-performance structures together with local materials.

Thanks to a modular construction scheme, the structure allows fast assembly and disassembly. The pre-assembled parts of the pavilion were mounted on-site in only 48 hours. Digital Bamboo offers a new paradigm for how digital fabrication can lead to a sustainable future in construction, combining locally sourced materials with 3d printed parts to achieve new immersive architectural expression.

We would like to acknowledge the effort and contributions of the class ‘20 students of the MAS in Architecture and Digital Fabrication at ETH Zurich.