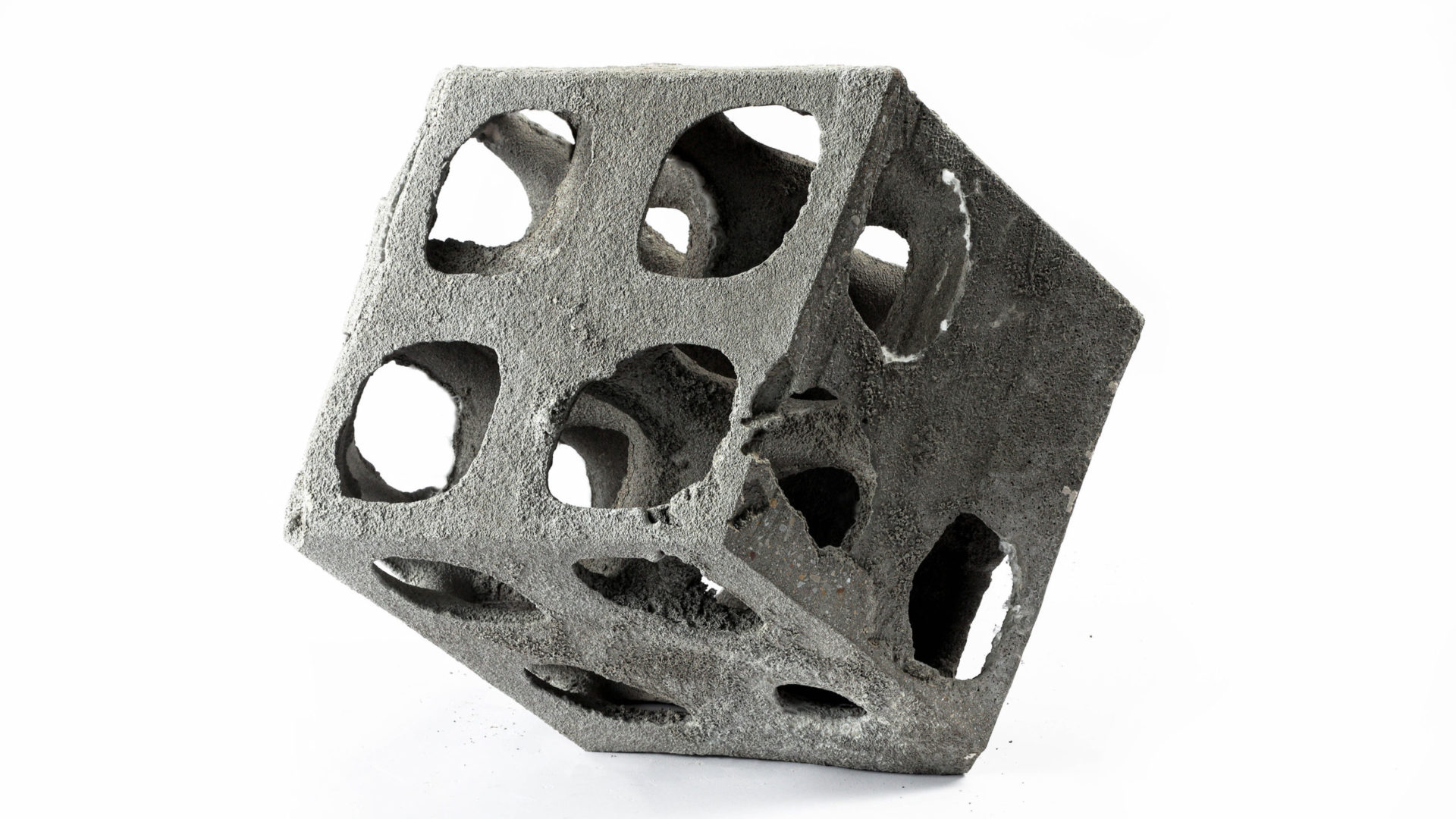

Cold Production explores a zero-waste fabrication method for concrete that uses digitally sculpted ice as a moulding material. The project explored spatial concrete lattices and their stacking principles.

Ice units were press-formed using 3D-printed multiparty moulds. The rapid and waste-free production is done in the Sub-Zero lab at -10C. The concrete was poured, cured, and the next day the elements were placed outdoors for demoulding by simply letting ice melt away, revealing its intricate concrete lattice design.

Customised computational tools were used from design to fabrication. The geometric pattern based on a dodecahedron honeycomb and the principle of its subdivision allowed to produce 24 module combinations with only with 6 types of ice units. The design tools were then used to maximise the variability of the lattice structure and to control the local and global densities of the lattice.

Artificial reality interfaces were also developed for the project workflow. Firstly, to support the design process, AR tools were developed to provide immersive visualization of the design in progress. Secondly, due to the complex reuse of the same moulds to create diverse variations, augmented reality headsets were integrated to support the manual assembly in the refrigerated environment of the lab.

The fabrication of the 15 unique lattice modules required the processing of 8400 kg of ice. For such a large scale of production, the raw material was sourced from a local ice rink. Ice abrasion is a common by-product of the regular resurfacing of the ice rinks. The reuse of ice for fabrication purposes allows an increase in the production speed and dramatically minimizes the energy consumption of the process.

The intertwined geometries of the concrete elements were assembled in a continuous structure. Based on the research on Ice Formwork, this project opens the potential of ice to cast concrete in topologically challenging forms and in a form that is applicable to architectural design.