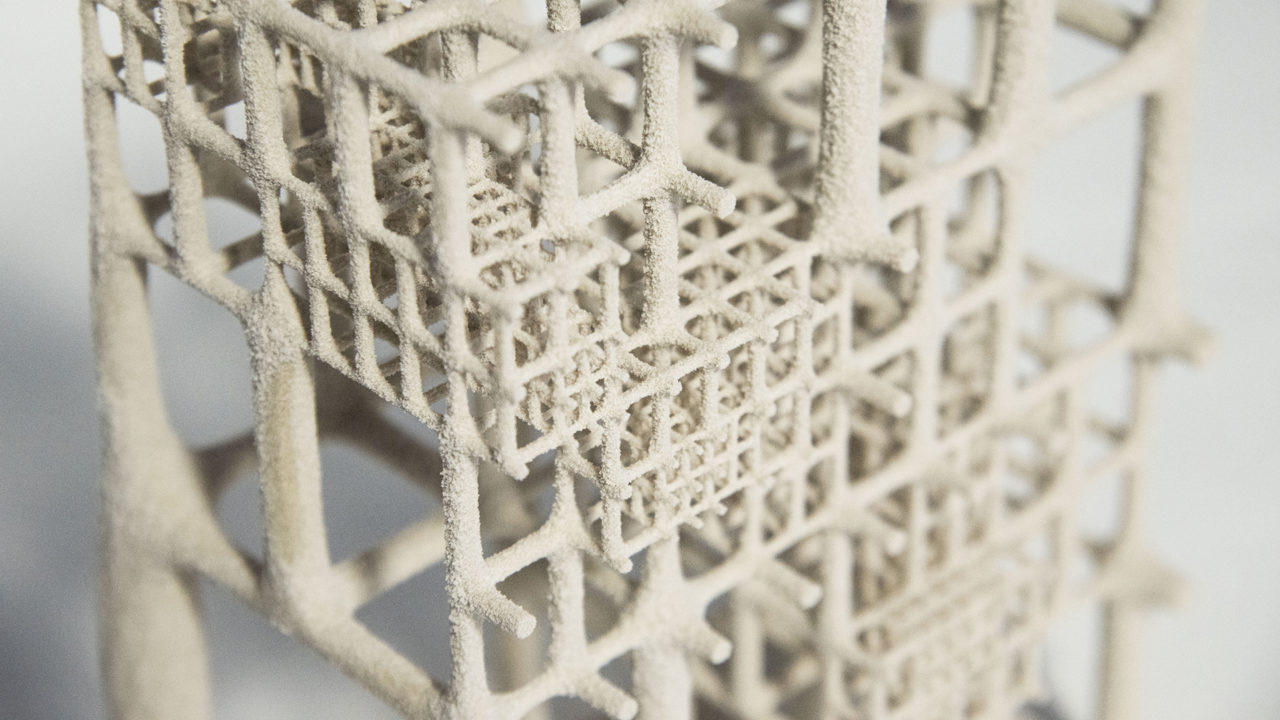

SmartBrick explores the production of specialized building components in a speculative manner. Over the course of two weeks, working in groups of two, the students developed computational design strategies for a construction element of their choice. Design drivers were among others, an embedded evaporation and ventilation system, acoustic absorption, structurally efficient material distribution, various degrees of porosity and transparency or precisely controlled, functionally graded translucency.

The successful realization of the 1:1 scale prototypes was made possible only by the chosen fabrication method, a large-scale sandstone binderjet 3D printer. For every student group, a maximum bounding box volume of 320 x 180 x 480 mm was available. Working in the Processing programming framework using Python, the students were introduced to generative computational design methods, mesh modification and subdivision strategies as well as volumetric modelling and the requirements to file preparation particular to additive manufacturing. Read more under www.masdfab.com.